Your Quickstart Guide to Ecommerce Business Inventory Management

You must master inventory management to develop a sustainable, lucrative, and scalable ecommerce business this year. Poor inventory management may be a difficult obstacle for any ecommerce entrepreneur to overcome, regardless of their level of skill, the size of their business, the sorts of products they offer, or the audience they serve.

As the year passes and you plan the launch of a new ecommerce business, you're probably thinking a lot about inventory management and how to approach and optimise it.

Making the wrong decisions about inventory management can be extremely expensive. Making the right decisions can be beneficial.

So, what do you need to know to succeed in the coming year?

This article will provide you with an overview of inventory management. First, we'll define a few words, then go through some of the issues that ecommerce business owners encounter, and finally, we'll give you a few concrete best practices and ideas to help you establish or optimise an effective inventory management plan for your company.

First Things First!

Before we get too deep into how to optimise inventory management, it's a good idea to first comprehend some of the phrases and concepts you'll come across. Here's a list of 20 terms and phrases to get acquainted with:

SKUs: A stock-keeping unit (SKU) is an identification code used to categorise and arrange merchandise.

Variants: Variations of the same product, for example, a different hue.

Inventory: Physical commodities, products, or goods intended for sale to customers.

Supply Chain: The procedures and systems involved in the manufacture, management, and distribution of a product.

Units of Measure: Methods that you employ to gauge your stock (items, pieces, bundles, kilograms, ounces, etc.).

Dead Stock: Inventory that you have on hand but are unable to sell.

Minimum Viable Stock: The bare minimum of product you must keep on hand to meet consumer demand and fulfil orders on time.

Buffer Stock: The quantity of excess stock kept on hand to mitigate risk when supply and demand are uncertain.

Lead Time: The time that elapsed between ordering the product from a supplier and receiving it.

Re-order Point (ROP): The level at which stocks or inventory must drop before necessitating the ordering of additional inventory.

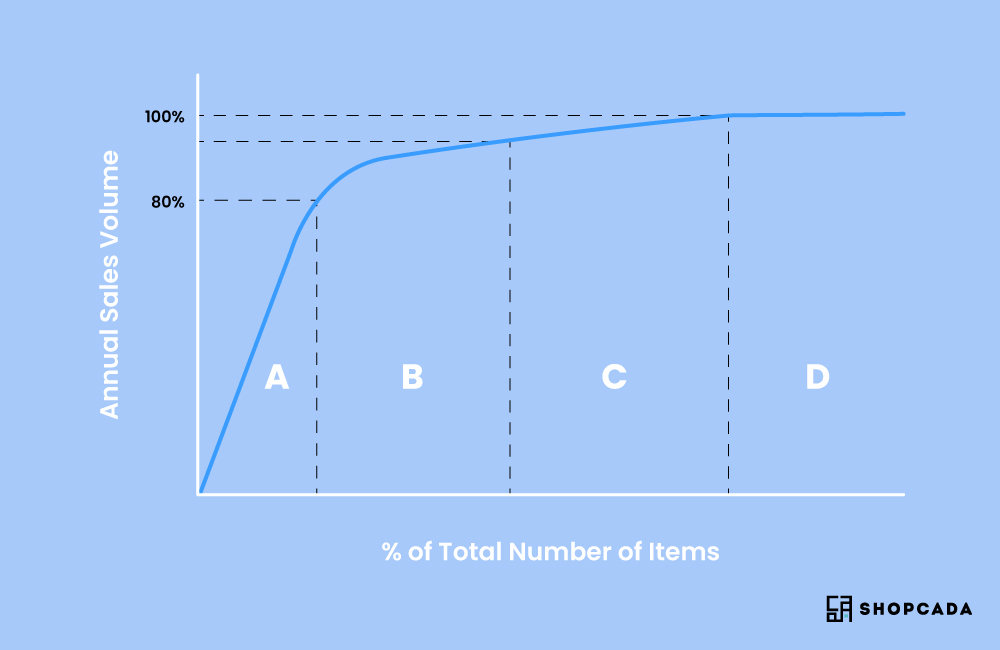

ABC Analysis: A method for categorising your existing inventory into three categories: (A) high-value products with a low frequency of sales; (B) moderate-value products with a moderate frequency of sales; and (C) low-value products with a high frequency of sales.

Just-in-Time (JIT): A fulfilment strategy in which inventory orders are placed precisely in time to meet consumer demand. This strategy avoids tying up money in unsold goods, but it introduces the danger of not being able to satisfy a sudden increase in requests.

Dropshipping: A fulfilment approach in which no inventory is stored on-site Instead, orders are fulfilled and the product is supplied directly to the client from a third party.

Centralised Inventory Control: Inventory management software that enables you to quickly manage, track, and control inventory across different ecommerce websites such as Amazon, eBay, and Etsy.

First in First Out (FIFO): An accounting technique presupposes that sellable assets purchased first, such as inventory, raw materials, or components, were sold first. That is, the oldest stuff is sold first, and the expenditures connected with it are used to calculate profitability.

Inventory Management Software: Tools for tracking inventory, streamlining operations, automating laborious chores, and leveraging data and other insights to increase success.

Cost of Goods Sold (COGS): An accounting item presented on the income statement that displays the entire expenses of a company's items or merchandise sold during a reporting period and is considered an expense.

Carrying Cost/Holding Cost: The annual cost of storing your inventory versus the worth of the goods itself

Inventory Forecasting: Making informed judgments about ordering and reordering products in your organisation based on previous data, trends, and seasonality.

Inventory Auditing: The act of manually counting or inspecting inventory to ensure that it corresponds to the quantities in your tracking and automation systems.

Understanding these words and concepts can help you become more knowledgeable and smart when managing and optimising inventory management procedures and duties at your company.

Challenges with inventory management in ecommerce

Every ecommerce business owner faces inventory management issues at some point. Knowing what some of these difficulties are and how you overcome them ahead of time is what distinguishes effective inventory management from exceptional management.

Here are some of the most typical inventory issues that can have an impact on an ecommerce business's growth and profitability, as well as customer experience and retention:

The first challenge is overstocking and overselling.

If you don't have a strong understanding of your inventory and the buying habits of your target audience, it's easy to find yourself in circumstances where you either can't fulfil demand or have overestimated how much product you truly need to have on hand in a given month.

Although keeping a big stock of goods on hand might be useful, especially as the busy season approaches, it can bring some challenges:

It can be costly. Unless you're doing dropshipping, you'll need to keep the things you order from manufacturers. As you might expect, having too much inventory and not enough orders can harm your ability to come out ahead at the end of the month.

There is a risk of having too much dead stock on hand. As previously stated, the dead stock is inventory that you can't sell since you have too much inventory and not enough demand. It happens when things expire or deteriorate over time, but it can also happen when trends and purchasing habits change.

On the other hand, not keeping an eye on your inventory might lead to unintended overselling—that is, allowing customers to purchase things that are out of stock. When you oversell a product, you generate customer service and reputation issues that might take time to resolve.

When it comes to working with ecommerce firms these days, consumers want openness. They want to know and trust that if you make a promise, you will keep it. When you oversell inventory, you risk delaying fulfilment and even jeopardising the trust you've earned with those who decided to order your goods. A simple solution would be to mark things as in or out of stock online so customers can view available amounts for themselves.

Manual management that does not allow for scale is the second challenge.

Scale is another inventory management issue that many online business owners encounter. It's relatively easy—and tempting—to manually manage and fulfil orders, even across numerous channels, when you're just starting with your ecommerce firm. However, as you strive to scale your firm to match the growing expectations of your customer base, it becomes much, much more challenging.

Scaling includes selling products on more channels, such as Amazon, Etsy, eBay, and Alibaba, for many ecommerce business owners. It also entails collaborating with several partners, dealers, and manufacturers. It may even imply storing inventory in several warehouses around the country.

When you rely solely on manual management methods, taking such efforts to build your ecommerce business is nearly impossible. Manual management also increases the possibility of data errors affecting inventory management. For example, this could result in clients overestimating or underestimating the quantity available to them.

Here are some instances of ineffective manual inventory management methods:

-

Tracking inventory counts with offline spreadsheets

-

Using a collection of disparate tools that aren't integrated or synchronised with one another

-

Using an offline program that does not support automatic real-time updates

-

Manually tracking and fulfilling orders with paper and pencil

When you're just getting started in the world of ecommerce, it can be tempting to track and manage inventory manually to save money and maintain control over all aspects of your business. To avoid and prepare for some of the issues outlined above, you must examine and plan to implement more scalable inventory management procedures, tactics, and technologies that support long-term growth.

Third, there is a lack of visibility across numerous channels and warehouses.

Another common issue that ecommerce business owners encounter as product demand rises and inventory management grow more sophisticated is a lack of visibility. Two major visibility issues might influence your capacity to meet demand and develop your business:

Insufficient visibility across several warehouses. As your company grows, you may find yourself collaborating with more manufacturers and warehouses to satisfy the increasing demands of your clients. Your goal is to have merchandise on hand and ready to go when demand spikes unexpectedly. However, without inventory management software, it can be difficult to maintain track of orders, inventory, and relationships across all warehouses, partners, and manufacturers.

Without total visibility throughout your whole inventory management system, it's tough to know which decisions must be taken and by when to continue increasing sales and satisfying consumer demand.

Keep in mind that even if some customers prefer one platform over another, they must have the same experience as customers who purchase on other platforms. This necessitates contact and engagement across several channels to ensure consistency in your brand experience, such as pricing and product availability.

Fourth, there is a lack of understanding.

Lack of data insights is the ultimate inventory management difficulty that many ecommerce business owners confront when it comes to inventory management. You must get obsessed with data to build your business and make decisions that support demand.

To increase profits, support growth, and cater to your customer's needs, you must understand how your inventory fluctuates over time, how demand changes over time and forecast what it will look like in the future when to reorder products when to scale back on products, and where breakdowns in your processes occur.

To capitalise or completely comprehend a developing opportunity, you often need to be able to obtain and act on inventory data within a day or even a few hours.

It's nearly hard to harness data to make these kinds of informed business decisions without a centralised system that pulls inventory information from every source in real-time, 24/7.

How to Begin Inventory Management

Now that you've grasped some of the principles and issues associated with inventory management in ecommerce, it's time to act. Take the following steps to create an optimal inventory management system for your online business:

1. Recognise basic product category demand

Understanding how demand fluctuates for your product category over time is the first step in improving inventory management, especially if you're opening a brand-new online site. This can be accomplished by using Google Trends to examine how search demand and interest have evolved over the last 12 months or even the last five years.

As you can see, in most years, interest begins to build as early as October and peaks between December and January. Understanding trends in this way allows you to better predict when you should order more or less of the things you sell.

If you already have an established ecommerce site, you can use Google Analytics to determine which pages and goods your audience visits the most and how much time they spend on them. This knowledge will tell you not just what types of products pique your audience's interest, but also which things are popular and necessitate extra buffer stock.

2. Project future demand based on previous sales.

The second phase in inventory management optimization is to try to estimate future demand, including seasonal demand. Simply examine previous sales to understand when demand and interest were at their peak. Look ahead to identify big selling opportunities throughout the year, such as holidays and events, and prepare for increasing demand.

Order and store inventory accordingly to avoid any items running out of stock during peak demand periods. If you don't have any sales history, turn back to the Google Trends and Google Analytics analysis.

3. Determine the first minimum viable stock or stock levels.

If your ecommerce store is already up and running, you should also define minimum viable stock levels for each product you sell. Remember that your goal is to have the least amount of inventory feasible to satisfy demand and prevent fulfilment delays.

To get at your figure, you must first assess demand and the time it takes to replace out-of-stock goods. Place a fresh order with your manufacturer or reseller when volumes fall below the number you specify. Consider this exercise to be a beginning point. Don't be scared to change this quantity over time as consumer demand increases or decreases.

4. Use an ABC analysis to prioritise products.

Take the time to prioritise products using the ABC analysis to increase productivity and save money. As previously stated, the ABC analysis is a way of categorising your existing inventory into three categories:

(A) High-value products with a low sales frequency. For example, large-ticket purchases such as exercise and sporting equipment.

(B) Items of a moderate value with a moderate frequency of sales. Electronics and jewellery are two examples.

(C) Low-value products with a high sales frequency. Clothing and food, for example.

The Pareto Principle, which states that 80% of your sales may be traced to 20% of your consumers, provides a foundation for ABC Analysis. These clients purchase category A products, which provide the vast majority of your revenue. As a result, losing these clients is more costly to your bottom line than losing customers who buy B and C products.

Your goal here should be to determine which products require the greatest attention from you in terms of inventory management. Those in your A category, for example, may need to be ordered more frequently than products in your C category because the amount you maintain on hand is significantly lower.

5. Prepare for seasonality.

If you own an ecommerce site that will benefit from a specific shopping season, such as the holidays, or time of year, such as summer, do everything you can to be ready.

During sluggish months, keep inventory levels low, but don't wait too long to ramp up your supply. To avoid carrying too much dead stock near the end of a peak season, promote special offers to sell off the majority of inventory.

Keep your operational costs as low as possible for as long as possible, and utilise the downtime to ensure you have all the pieces in place—partners, tools, warehouse storage, personnel resources, equipment, and so on—to ensure a smooth and profitable sales period.

6. Install inventory management software.

Inventory management software is essential for building and scaling an ecommerce business today. You can manually implement some of the suggestions given above, but as previously said, this will not make scaling your business easier.

Inventory management software can assist you in keeping a pulse on inventory, ensuring you're never overstocked or understocked, synchronising inventory tracking across all the channels you sell products on, compiling real-time inventory data within one convenient system, and leveraging valuable insights that you can use to capitalise on opportunities, boost sales, and grow your ecommerce business.

7. Physically manage smarter.

Don’t forget that you sometimes need to get hands-on as well. Sure, automation and software are all good and very swell, but at the end of the day, someone’s still got to get things done. Here is where smart warehouse management comes in. Try introducing racks to better separate products and ensure inventory is accurately stored and easy to find as well as pack. This reduces the time spent in the warehouse for your staff and with an organised warehouse, there’d be less of a chance for inventory to go missing!

Consider your inventory management approach

There are a few questions you should ask yourself as you consider enhancing inventory management for your online firm. For instance, how do you approach inventory management in your company? What difficulties have you confronted and overcome? What lessons have you learned that you can share with other entrepreneurs and business owners?

The answers to these questions will influence how you adopt inventory management, how your company grows, and how you continue to meet your consumers' expectations.